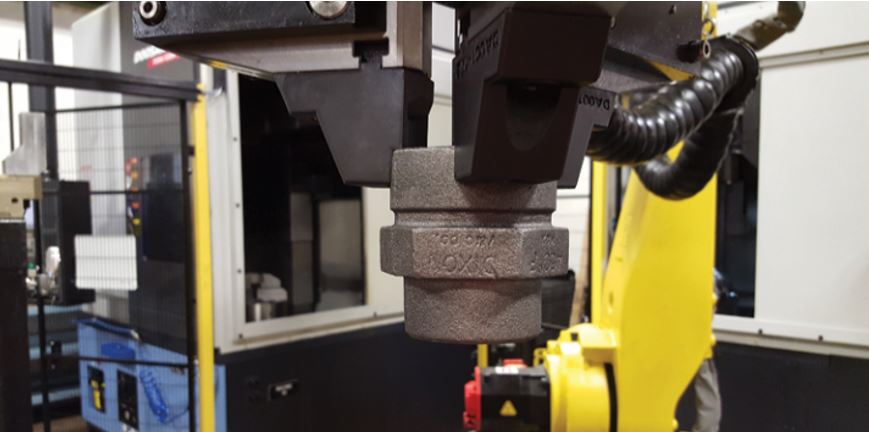

Another great example of reinforced 3D printed parts on the shop floor is end-of-arm vacuum tooling. When lightweight, flat parts need to be moved around and assembled, it’s common to use vacuum tooling to use air and suction parts to hold and move them. The image below shows a blue tube that is pulling air through the black tool. This creates the suction necessary to lift and move these lightweight parts.

There are a handful of properties these vacuum tools can require that 3D printing excels at. First, the tool should be lightweight because it is attached to the end of a robotic arm. Second the air suction needs to be routed through internal channels to provide suction at multiple locations. Finally, the tool needs to fit a unique contour of the part it’s picking up. Fiber reinforced 3D printed parts are the perfect solution for strong, stiff, lightweight, custom geometry vacuum tooling.

Keep in mind, these vacuum tools are typically only needed in very low quantities (1-10 parts) which is perfect for additive manufacturing. There’s no need to book time on a CNC mill and fixture an aluminum block for machining. This makes it much quicker to iterate new designs as well.

Using data from another Markforged case study, these numbers show the difference between aluminum and fiber reinforced vacuum tooling.